Double Layer Bags: The Strategic Sweet Spot in an Era of Layered Performance Demands

In the dynamic world of flexible packaging, finding the optimal balance between performance, cost, and sustainability is paramount. Double Layer Bags represent a crucial middle ground, offering significant advantages over simpler structures while often avoiding the complexity and cost of their more robust counterparts. As market demands evolve and sustainability pressures intensify, understanding the strategic role of Double Layer Bags, alongside when Triple Layer Bags become essential, is critical for converters and brands navigating the future.

The Evolving Performance Landscape: Beyond Single Layer

While Single Layer Bags excel in recyclability and cost for basic applications, many products require enhanced protection. This is where Double Layer Bags step in. By combining two distinct polymer layers, these structures unlock significant performance upgrades:

Enhanced Barrier Properties: A key inner layer (e.g., PE for moisture resistance) can be paired with an outer layer offering different characteristics (e.g., OPP for stiffness, printability, or light barrier). This synergy provides far superior protection against moisture, oxygen, and contaminants compared to single films.

Improved Strength and Durability: The lamination of two films inherently creates a tougher, more puncture-resistant, and tear-resistant package, crucial for heavier products or demanding supply chains, especially e-commerce.

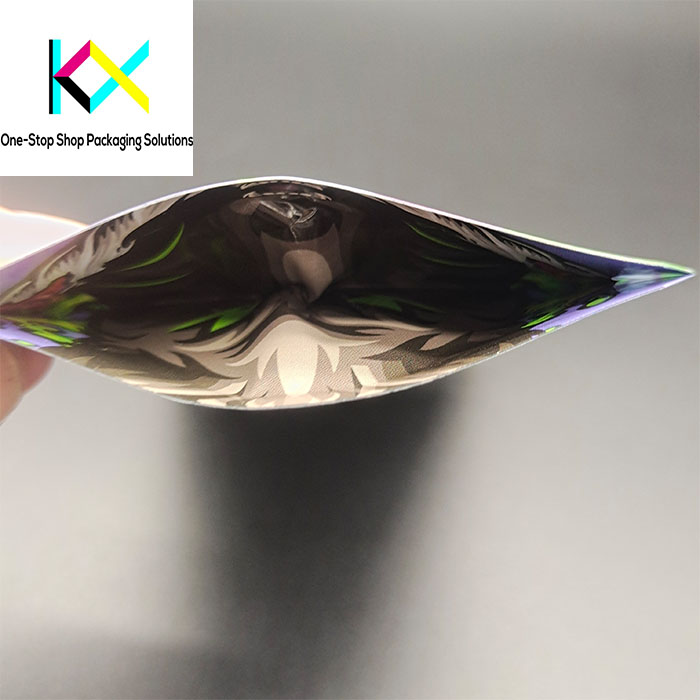

Superior Printability and Aesthetics: An outer layer specifically chosen for its excellent print surface allows for vibrant, high-definition graphics and metallized finishes, enhancing shelf appeal without compromising the protective function of the inner layer.

Functional Versatility: Double Layer Bags readily accommodate features like resealable zippers or easy-tear notches, offering consumer convenience without venturing into the complexity of pouches.

The Driving Forces Behind Double Layer Dominance

Several converging trends solidify the position of Double Layer Bags as a strategic workhorse:

Extended Shelf Life Requirements: Consumers and retailers increasingly demand fresher products for longer. Double Layer Bags provide the necessary barrier (moisture, oxygen) to significantly extend shelf life for snacks, coffee, pet food, and dry goods, reducing food waste – a major sustainability win.

E-commerce Resilience: The surge in online shopping demands packaging that survives the “last mile.” The inherent toughness of Double Layer Bags offers better protection against crushing, punctures, and abrasion during shipping and handling compared to single-layer options.

Cost-Effective Performance: While more expensive than single-layer, Double Layer Bags typically offer a significantly better price-to-performance ratio than Triple Layer Bags. They deliver substantial functional improvements without the full cost burden of adding a third layer, making them ideal for mid-tier products and performance-sensitive markets.

Material Efficiency (vs. Pouches): For many dry and semi-dry products, well-designed Double Layer Bags can offer comparable protection to stand-up pouches but often with less total material usage and simpler manufacturing processes.

When Three Layers Triumph: The Triple Layer Imperative

Despite the versatility of double-layer constructions, Triple Layer Bags remain indispensable for specific high-demand applications. Adding a third layer unlocks critical advantages:

Ultra-High Barrier Performance: Triple Layer Bags excel where maximum protection is non-negotiable. They can incorporate dedicated high-barrier polymers (like EVOH or metalized films) between protective inner and outer layers, creating an exceptional shield against oxygen, moisture vapor, aromas, and light. This is essential for sensitive products like premium coffee, spices, certain pharmaceuticals, and high-value nutraceuticals.

Enhanced Strength and Abuse Resistance: For extremely heavy, sharp, or abrasive contents, or for packaging requiring very long shelf life under variable conditions, the added robustness of a Triple Layer Bag is often necessary.

Specialized Functionality: Complex needs, such as integrating peelable seals for easy opening or specific gas-flushing requirements for modified atmosphere packaging (MAP), often mandate the structural complexity achievable with three or more layers.

Balancing Conflicting Properties: A third layer allows converters to precisely engineer solutions where outer layer requirements (print, gloss, stiffness) conflict with inner layer needs (sealability, food contact safety) or barrier demands.

Sustainability: Navigating the Layer Complexity Conundrum

The sustainability equation for multi-layer bags is nuanced:

Double Layer Bags: Present a more manageable challenge than Triple Layer Bags due to fewer material combinations. Efforts focus on using compatible polymers (e.g., all-PE or all-PP structures where possible), incorporating recycled content (PCR), and lightweighting each layer. They offer a balance – better protection potentially reducing product waste versus single-layer, while being inherently more recyclable than many complex pouches or rigid packs.

Triple Layer Bags: Face greater recyclability hurdles due to the increased likelihood of mixed materials. The focus intensifies on:

Monomaterial Triplex: Developing Triple Layer Bags using only one polymer family (e.g., PP/PP/PP) with specialized coextruded films providing barrier within the mono-material structure.

Advanced Sorting: Supporting investments in enhanced recycling infrastructure capable of identifying and separating complex laminates.

Chemical Recycling: Positioning these high-performance, hard-to-recycle mechanically Triple Layer Bags as prime candidates for emerging chemical recycling technologies that break polymers back to monomers.

Lifecycle Analysis (LCA): Justifying the environmental footprint by demonstrating significant shelf-life extension and product waste reduction that outweighs the packaging impact.

Innovation Focus: Smarter Layers for Future Needs

Research and development are pushing boundaries for both categories:

Double Layer Bags: Innovations target thinner gauge films with equal or better performance, higher incorporation of PCR content, improved recyclable mono-material structures (beyond just PE or PP), and enhanced barrier coatings applied to simpler substrates.

Triple Layer Bags: The drive is strong towards true monomaterial solutions with coextruded high-barrier layers, developing thinner yet equally effective barrier films, utilizing bio-based or compostable polymers where applicable for specific layers, and integrating smart packaging elements (like RFID or freshness indicators) within the laminate structure.

Choosing Wisely: Strategic Application is Key

The decision between two and three layers isn’t arbitrary; it’s a strategic calculation:

-

Opt for Double Layer Bags When: Robust moisture/oxygen barrier, good puncture resistance, strong print quality, and cost-effectiveness are required for products like dry mixes, cereals, standard snacks, pet treats, hardware items, or as secondary e-commerce packaging. They offer the best “bang for buck” in mid-range performance needs.

-

Require Triple Layer Bags When: Maximum barrier protection (especially O2), extended shelf life for highly sensitive products, defense against sharp contents, or specific functional needs (like MAP) are critical. Essential for premium coffee, specialty spices, certain medical devices, high-value nutritional supplements, and aggressive industrial components.

The Future: Precision Engineering and Circular Solutions

The trajectory points towards more intelligent layer deployment:

-

Right-Sizing Layers: Converters and brands will increasingly utilize sophisticated modeling and testing to determine the minimum number of layers needed for a specific product’s requirements, avoiding unnecessary complexity. Double Layer Bags will often be the optimized solution.

-

Monomaterial Breakthroughs: Expect accelerated development of high-performance monomaterial films suitable for both Double Layer Bags and Triple Layer Bags, dramatically improving recyclability without sacrificing protection.

-

Hybrid Technologies: Combining coextrusion with advanced coatings or surface treatments will create thinner, higher-performing laminates, potentially reducing the need for moving from double to triple layers in some cases.

-

Infrastructure Collaboration: The success of sustainable multi-layer bags, especially Triple Layer Bags, hinges on collaborative efforts across the value chain to build collection, sorting, and advanced recycling capabilities.

Conclusion: Mastering the Middle Ground

Double Layer Bags are far more than just a step above single-layer; they represent a strategically vital sweet spot in flexible packaging. They deliver a compelling combination of enhanced performance, cost efficiency, and a more manageable path towards sustainability for a vast array of products. While Triple Layer Bags remain essential for the most demanding applications, continuous innovation aims to narrow the performance gap and improve their environmental profile. For brands and converters, success lies in precise engineering – deploying the optimal number of layers (Double Layer Bags where sufficient, Triple Layer Bags where essential) to meet product protection needs, consumer expectations, and sustainability goals without over-engineering or over-spending. Mastering this layered approach is fundamental to thriving in the sophisticated future of flexible packaging。