The Packaging Revolution: How Custom Printed Stand Up Pouches Are Transforming Brand Experiences

The modern custom printed stand up pouch represents far more than a container—it’s a powerful brand ambassador, a sustainability statement, and a technological marvel all in one. As consumer expectations evolve and environmental regulations tighten, these versatile packaging solutions are undergoing remarkable innovations, particularly in rotogravure printing pouch production. The industry is witnessing five fundamental shifts that are redefining what flexible packaging can achieve.

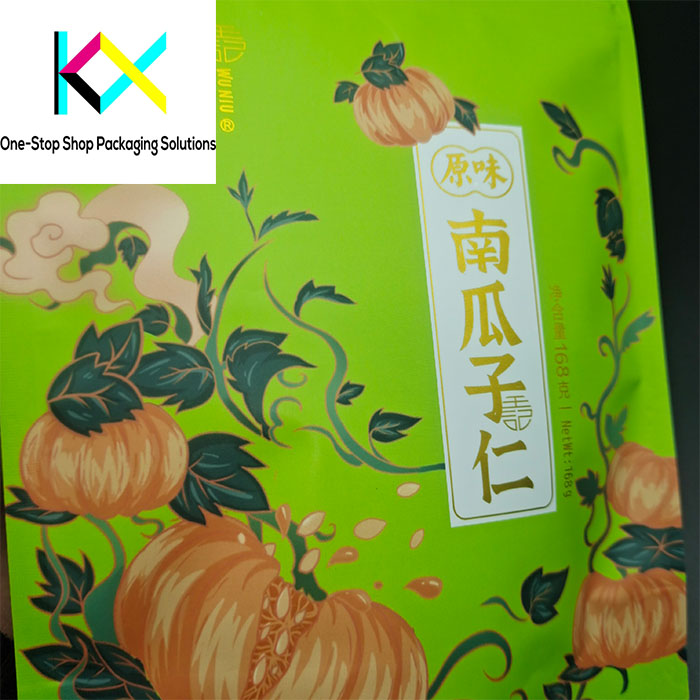

1. The Renaissance of Print Quality: Where Art Meets Science

Today’s custom printed stand up pouches showcase printing capabilities that were unimaginable just five years ago. Advanced rotogravure printing pouch technology now delivers:

10-color process printing with 250 LPI resolution for photorealistic imagery

Sub-micron engraving precision creating textures you can feel

Expanded gamut systems matching 98% of Pantone colors

Hybrid metallic inks that shift color at different angles

Luxury brands like Godiva and Häagen-Dazs have adopted these technologies for limited-edition collections, using:

• Mirror-finish foils that reflect like liquid metal

• Thermochromic inks that change color when chilled

• Micro-embossed patterns mimicking artisan craftsmanship

The result? Packaging that consumers keep long after the product is gone—with some limited-edition custom printed stand up pouches selling for premium prices on secondary markets.

2. The Sustainability Imperative: Beautiful Packaging That Doesn't Cost the Earth

Environmental concerns are driving unprecedented innovation in rotogravure printing pouch materials and processes:

Breakthrough Materials

Monomaterial laminates achieving 95% recyclability without compromising barrier properties

Marine-degradable films breaking down in saltwater within 24 months

Plant-based inks derived from algae and vegetable oils

Process Revolution

Water-based gravure inks reducing VOC emissions by 90%

Cylinder refurbishment programs extending tooling life 5x

Digital asset management minimizing setup waste by 40%

Leading brands like Tony’s Chocolonely now use custom printed stand up pouches made from 70% post-consumer recycled content, proving sustainability and premium aesthetics can coexist.

3. Smart Packaging 2.0: When Your Pouch Becomes Interactive

The next generation of rotogravure printing pouch solutions incorporate astonishing functionality:

Consumer Engagement Features

NFC-enabled panels triggering augmented reality experiences

Conductive ink circuits creating touch-sensitive surfaces

Micro-encapsulated scents releasing when rubbed

Supply Chain Intelligence

Time-temperature indicators showing freshness

UV-visible batch codes for authentication

Edible QR codes printed with food-grade inks

PepsiCo’s recent snack line features custom printed stand up pouches that:

✓ Play videos when scanned

✓ Change color if exposed to heat

✓ Provide recycling instructions via AR

4. The E-Commerce Evolution: Packaging That Survives the Digital Supply Chain

As DTC sales explode, rotogravure printing pouch designs are being reengineered for logistics:

Structural Innovations

Hexagonal air-cell cushioning absorbing 50G impacts

Self-healing films sealing micro-punctures automatically

Phase-change materials maintaining temperature for 72 hours

User Experience Enhancements

One-hand opening systems with magnetic closures

Integrated measuring guides for portion control

Peel-reseal labels maintaining freshness through multiple uses

Amazon’s packaging certification program now favors custom printed stand up pouches with:

• Compression-resistant bases

• Abrasion-proof exteriors

• Flat-panel surfaces for labeling

5. The Future of Brand Expression: Packaging as a Cultural Artifact

Forward-thinking companies are elevating rotogravure printing pouch solutions to art forms:

Cultural Storytelling

-

Collaborations with local artists for regional editions

-

Augmented reality murals that come alive when scanned

-

Evolving designs that change with seasons or trends

Educational Platforms

-

Interactive ingredient journeys

-

Recipe generators based on remaining quantity

-

Sustainability impact calculators

The most innovative custom printed stand up pouches now serve as:

→ Collectible art pieces

→ Cooking instructors

→ Environmental educators

The Road Ahead

As we look to the future, several emerging technologies promise to further transform rotogravure printing pouch production:

-

AI-driven design systems creating infinite packaging variations

-

3D-printed cylinders reducing engraving time by 80%

-

Bio-luminescent inks glowing to indicate freshness

-

Self-cleaning surfaces using nano-coatings

The custom printed stand up pouch has evolved from simple wrapper to multidimensional brand interface—one that informs, protects, delights, and even educates. In an increasingly digital world, these tactile, visually stunning packages represent perhaps the most powerful physical connection between brands and consumers.

You can visit our website to know more about our flexible packaging pouch: