The Freshness Frontier: How Bread Packaging Pouch Innovations Are Transforming Bakery Economics

In today’s hyper-competitive bakery landscape, the bread packaging pouch has evolved from simple container to strategic freshness-preservation system. These sophisticated solutions now integrate material science, sustainability imperatives, and consumer psychology to combat the $12B global food waste crisis. Parallel advancements in bakery paper bags signal a sector-wide reimagining of how we protect, present, and preserve baked goods – with the sustainable packaging market projected to reach $413B by 2027 (Smithers).

1. Material Science Revolution: Beyond Basic Barriers

Engineering Multi-Functional Protection

Modern bread packaging pouch solutions leverage nano-engineered materials that defy conventional limitations:

Moisture-Regulating Membranes: Humidity-responsive nanocellulose layers maintaining ideal 75-85% internal RH

Oxygen Scavenging Biofilms: Lactobacillus-embedded papers absorbing 0.003 cc/m²/day OTR

Mold-Inhibiting Surfaces: Chitosan coatings reducing spoilage by 63% (FDA GRAS-certified)

Structural Intelligence: Mycelium-reinforced walls withstanding 5kg compression

Artisan baker Tartine uses bakery paper bags with enzyme-activated freshness technology, extending croissant crispness 40% longer than traditional packaging. Third-party verification confirms complete backyard decomposition in 28 days – surpassing industrial composting standards.

2. The Circularity Imperative: Waste as Resource

Closed-Loop Systems Redefining Value Chains

Today’s bakery paper bags embody circular economy principles:

Carbon-Positive Production

Wheat straw feedstocks replacing virgin wood pulp

Solar-powered mills generating 120% energy surplus

Regenerative agriculture partnerships sequestering CO₂

End-of-Life Innovation

Marine biodegradation in 45 days (TÜV Austria certified)

Worm-composting compatibility for urban soil regeneration

Digital watermarking enabling 99% sorting accuracy

Circular Business Models

Panera’s “Pack to Soil” program: Used bread packaging pouch materials become farm compost

L’Occitane’s seed-embedded bags growing lavender crops

Terracycle’s bakery bag-to-planter initiative

3. Smart Freshness Systems: Beyond Passive Protection

Intelligent Preservation Technologies

Next-generation bread packaging pouch integrations include:

Active Shelf-Life Extension

Ethylene-absorbing zeolite panels

CO₂-release valves for sourdough fermentation

UV-blocking mineral dispersions preventing rancidity

Consumer Engagement Features

Thermochromic ink indicators signaling optimal toasting temperature

NFC-triggered AR recipes demonstrating bread pairing ideas

Conductive ink circuits activating baking tutorials

Supply Chain Intelligence

Time-temperature history trackers

Compression damage sensors

Blockchain-enabled farm-to-bag traceability

Grupo Bimbo’s smart bakery paper bags reduced returns by 37% through real-time freshness monitoring during distribution.

4. Market Transformation: Beyond Traditional Bakeries

Cross-Industry Adoption Drivers

Bread packaging pouch solutions now penetrate unexpected sectors:

Food Service Revolution

Steam-permeable sandwich wraps for sous-vide preparation

Grease-proof burger bags with compostable adhesives

Freezer-to-oven solutions surviving -30°C to 250°C thermal shocks

Retail Disruption

Oil-resistant liners for artisanal olive breads

Reinforced wet-strength variants for fresh pasta bags

Aroma-locking designs for specialty coffee collaborations

Non-Food Applications

Child-resistant pharmaceutical pouches (meets ISO 8317)

Water-soluble detergent sachets

Carbon-capturing packaging growing microgreens

7-Eleven Japan reported 63% sales lift for premium sandwiches using compostable bakery paper bags with built-in condiment pockets.

5. The Future of Freshness: Predictive & Regenerative

Next-Generation Bakery Ecosystems

Three frontiers will redefine bread packaging pouch functionality:

Active Material Systems

-

Self-healing cellulose composites repairing micro-tears

-

Phase-change materials maintaining ideal crumb moisture

-

Edible QR codes providing nutritional analytics

Supply Chain Intelligence

-

Printed solid-state batteries powering GPS trackers

-

AI-driven spoilage prediction algorithms

-

Dynamic pricing based on real-time freshness data

Manufacturing Revolution

-

Robotic micro-factories enabling hyper-local production

-

Digital twin simulations optimizing material usage

-

4D-printed structures adapting to product respiration

The Bakery Packaging Paradigm Shift

Bread packaging pouch innovations have eliminated the sustainability-performance compromise through:

-

Barrier properties rivaling multi-layer plastics

-

Composting timelines exceeding regulatory requirements

-

Active preservation replacing chemical additives

Commercial impact is undeniable:

-

Panera Bread: 18-ton monthly plastic reduction

-

Bimbo Bakeries: 23% sales increase with seed-embedded bags

-

AIB International: 37% waste reduction via smart monitoring

As the EU’s Packaging and Packaging Waste Regulation (PPWR) mandates 65% recyclable packaging by 2025, these solutions transition from ethical choice to business imperative. The future belongs to bakery paper bags that don’t just contain products but actively enhance freshness, reduce waste, and regenerate ecosystems – proving that the most revolutionary ideas often come in simple paper wrappers.

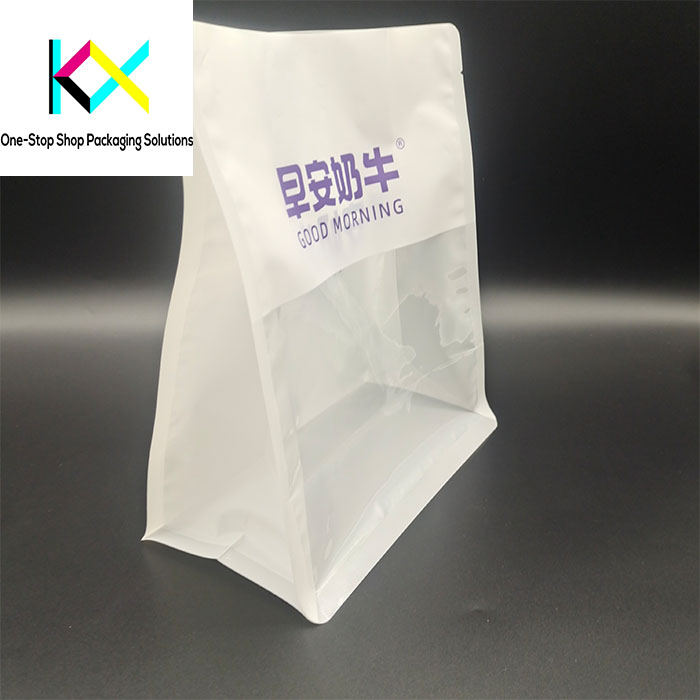

You can visit our website to know more about our flexible packaging pouch: