The Unseen Engine: How Composite Packaging Bags Drive Modern Brand Value with Digital Precision

The world of flexible packaging hums with innovation, yet few components are as fundamentally crucial yet often overlooked as the Composite Packaging Bag. These sophisticated structures, meticulously engineered from layers of diverse materials, form the protective heart of countless products lining our shelves – from gourmet coffee and premium pet food to pharmaceuticals and industrial chemicals. Far from simple containers, they represent a pinnacle of material science, balancing critical barriers against moisture, oxygen, light, and contaminants with demands for lightweight efficiency, durability, and increasingly, stunning visual appeal. It is precisely within this realm of high-performance protection that Digital Printing Packaging emerges as a transformative force, injecting unprecedented flexibility, speed, and creative potential into the production of these essential vessels. Together, they are reshaping brand strategies and consumer experiences in the dynamic soft packaging landscape.

1. The Alchemy of Protection: The Science Behind Composite Packaging Bags

The enduring dominance of the Composite Packaging Bag stems from its ability to achieve what no single material can. Imagine safeguarding delicate roasted coffee beans: they need an oxygen barrier to prevent staleness, a moisture barrier to avoid sogginess, light protection to preserve flavor compounds, and structural integrity to withstand handling. A single polymer film struggles to deliver all these properties simultaneously without compromise (excessive thickness, poor machinability, high cost). The solution lies in lamination or co-extrusion, combining distinct layers:

Functional Layers: Polyethylene (PE) or cast polypropylene (CPP) provide excellent heat-sealability. Aluminum foil offers near-total barrier properties. Ethylene Vinyl Alcohol (EVOH) delivers exceptional oxygen barrier, crucial for oxygen-sensitive products. Polyamide (Nylon) provides strength, puncture resistance, and temperature stability.

Structural Synergy: Each layer contributes specific properties. The result is a lightweight yet robust Composite Packaging Bag with tailored protection far exceeding the sum of its parts. This multi-layered approach allows for ultra-thin gauges, minimizing material use while maximizing performance – a key sustainability advantage through source reduction.

Beyond Basic Barriers: Modern composites integrate advanced functionalities. High-barrier transparent films using SiOx or AlOx coatings offer glass-like clarity with strong protection, replacing foil for premium see-through appeal. Active packaging layers can absorb oxygen or ethylene, extending shelf-life dramatically. Intelligent layers incorporating sensors (for temperature, freshness) are emerging, though integration into flexible composites remains a frontier.

Machinability Matters: The chosen composite structure must run efficiently on high-speed form-fill-seal (FFS) machinery. Factors like seal integrity, stiffness, coefficient of friction, and resistance to flex cracking are critical engineering considerations inherent in Composite Packaging Bag design.

The complexity of these structures underscores their value. They are not merely bags; they are precisely calibrated protective systems engineered for specific product vulnerabilities and logistical challenges. The rise of e-commerce has further amplified the need for composites that withstand the rigors of shipping – demanding enhanced puncture resistance and durability within the Composite Packaging Bag paradigm.

2. The Digital Revolution: Unleashing Creativity and Agility in Packaging

While composites provide the protective foundation, Digital Printing Packaging is fundamentally altering the surface expression and economic model of producing these bags. Unlike traditional analog methods (flexography, gravure) requiring engraved cylinders or plates for each design element and color, digital printing deposits ink directly onto the substrate (film, paper, foil) based on digital files. This paradigm shift brings profound advantages:

Elimination of Plate Costs & Setup Time: The most immediate impact. No physical plates mean no upfront tooling costs (often thousands of dollars per design) and dramatically reduced setup/changeover times – shifting from hours to minutes. This removes a major barrier to design iteration and short runs.

Unlimited Design Freedom & Complexity: Digital Printing Packaging breaks the constraints of fixed color stations and cylinder repeats. Photographic quality, intricate patterns, gradients, variable data (unique codes, personalized messages), and an expanded color gamut (including Pantone-matching and special effects like whites, metallics, fluorescents) are achievable without extra cost or complexity. Brands can finally treat the Composite Packaging Bag as a true canvas.

Agility & Speed-to-Market: Reacting to trends, launching limited editions, testing regional variations, or addressing urgent supply chain shifts becomes feasible. Brands can order smaller quantities economically, reducing inventory risk and obsolescence. This agility is crucial in fast-moving consumer goods (FMCG) markets.

Cost-Effectiveness for Short Runs: For quantities below a certain threshold (constantly decreasing as technology advances), digital printing becomes the most economical solution. This opens the door for niche brands, premium limited editions, and customized promotional packaging previously unviable with analog printing on complex Composite Packaging Bag structures.

Enhanced Sustainability Potential: While ink chemistry remains an area of development, digital printing reduces waste significantly compared to analog setups: no plate washing solvents, minimal substrate waste during setup, and reduced overproduction due to economical short runs.

The adoption of Digital Printing Packaging is accelerating rapidly, driven by technological advancements in printheads (higher resolution, faster speeds), ink formulations (improved adhesion, broader substrate compatibility, food safety), and workflow software. Its integration with composite structures, however, presents unique challenges around ink adhesion to diverse surfaces (especially non-porous films and foils) and curing requirements, which the industry is actively solving.

3. The Synergistic Edge: Where Composite Performance Meets Digital Expression

The true power emerges when the robust functionality of the Composite Packaging Bag seamlessly integrates with the creative and operational flexibility of Digital Printing Packaging. This synergy unlocks new dimensions of value:

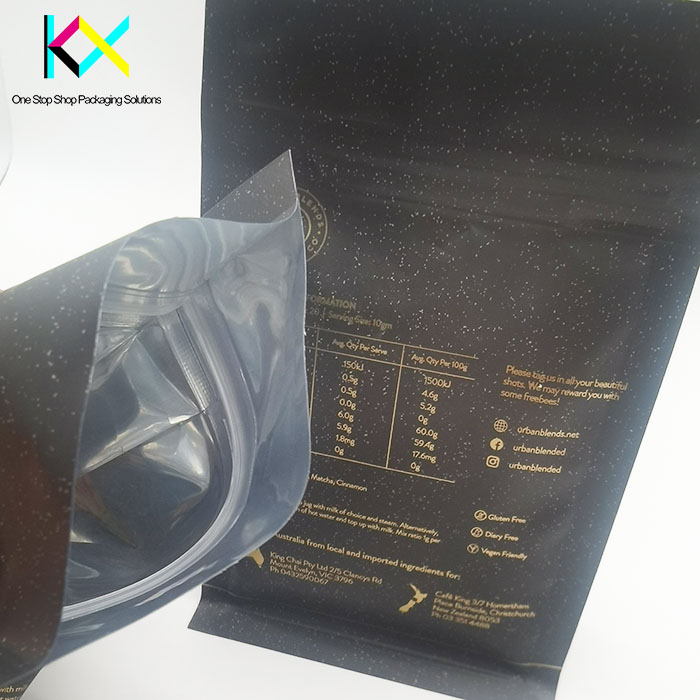

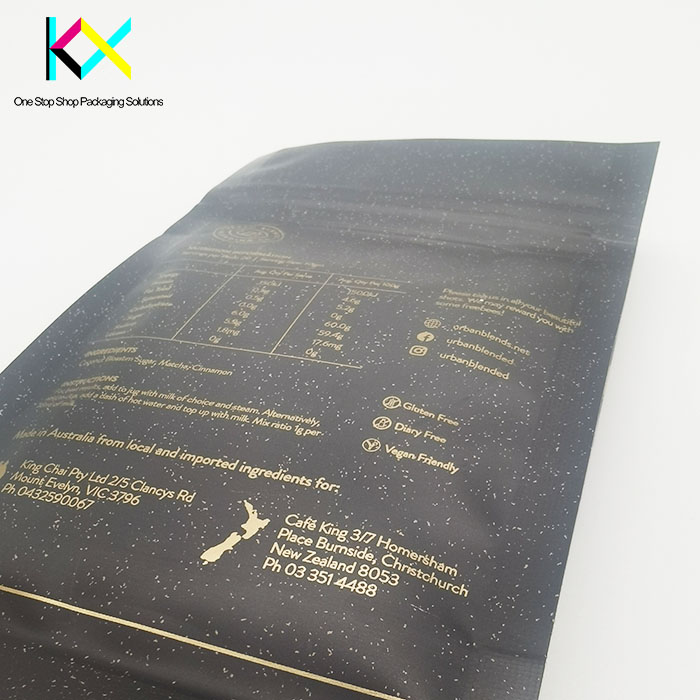

Premiumization through Visual Impact: High-barrier transparent composites combined with high-fidelity digital printing create stunning “window to the product” effects with vibrant, detailed graphics directly on the film. This elevates shelf presence for premium food, beverages, and health products housed within the Composite Packaging Bag.

Personalization & Customization at Scale: Imagine personalized pet food bags with the pet’s name and photo, or region-specific coffee blends with localized artwork, all printed digitally onto high-performance composite structures. Digital Printing Packaging makes tailored marketing and consumer connection feasible without sacrificing the essential protective qualities of the composite.

Rapid Prototyping & Design Validation: Brands can now produce small batches of actual Composite Packaging Bags with digital printing for consumer testing, focus groups, or retail buyer presentations far quicker and cheaper than traditional methods. This accelerates innovation cycles and reduces launch risk.

Enhanced Brand Storytelling & Transparency: The design freedom allows for more space dedicated to storytelling, ingredient transparency, sustainability credentials, or usage instructions directly on the primary package. QR codes printed digitally can link to dynamic content, further enriching the consumer experience tied directly to the Composite Packaging Bag.

Supply Chain Resilience & Efficiency: The ability to print smaller batches digitally reduces the need for massive centralized print runs and global shipping of pre-printed rolls. Distributed manufacturing models become more viable, with composite films printed closer to the filling location, shortening lead times and reducing logistics costs and carbon footprint.

This convergence allows brands to move beyond viewing packaging purely as a protective necessity. The Composite Packaging Bag, enhanced by digital printing, becomes an active brand asset, a dynamic communicator, and a tool for deeper consumer engagement, all while maintaining its core protective function.

4. Transforming the Supply Chain: On-Demand Manufacturing and Reduced Waste

The combination of Composite Packaging Bags and Digital Printing Packaging is catalyzing a shift towards more responsive, demand-driven manufacturing models, fundamentally impacting the supply chain:

Mass Customization Becomes Reality: The economic viability of short runs enables true mass customization. Brands can offer personalized versions of products or create hyper-targeted packaging variations for specific demographics, events, or retailers without massive minimum order quantities (MOQs) for the printed component.

Dramatic Reduction in Inventory: Gone are the days of warehouses filled with months’ worth of pre-printed packaging rolls, vulnerable to design changes or demand fluctuations. Digital Printing Packaging enables a “print-what-you-need, when-you-need-it” approach for the graphics, significantly slashing inventory carrying costs and the risk of obsolete packaging, even for complex Composite Packaging Bag formats.

Regionalization & Localization: Brands can efficiently produce packaging with region-specific languages, regulatory information, promotions, or even locally resonant designs. Digital printing facilitates this without the logistical nightmare and cost of managing multiple pre-printed roll stocks for different markets.

Minimized Pre-Production Waste: Analog printing setup generates significant substrate waste during plate mounting, color matching, and registration. Digital printing drastically reduces this “make-ready” waste, contributing to a more sustainable production process for the Composite Packaging Bag.

Faster Response to Market Dynamics: Whether reacting to a viral trend, a competitor’s move, a supply chain disruption affecting a specific product line, or a regulatory change requiring label updates, digital printing allows brands to adapt their Composite Packaging Bag graphics swiftly and cost-effectively.

This shift towards agility and reduced waste is a significant competitive advantage. It allows brands to be more consumer-centric, responsive, and efficient, aligning packaging production much more closely with actual market demand and reducing the environmental burden associated with overproduction and obsolescence.

5. Navigating Challenges and Embracing the Future

While the trajectory is clear, integrating sophisticated Composite Packaging Bags with advanced Digital Printing Packaging is not without its hurdles. Addressing these is key to unlocking the full potential:

Material Compatibility & Performance: Ensuring robust ink adhesion, scratch resistance, and chemical resistance on diverse composite surfaces (especially non-porous foils and films) remains a focus. Ink manufacturers and substrate producers are collaborating on advanced primers and surface treatments. Curing technologies (UV-LED, EB) also need optimization for different film types within the composite structure.

Print Speed & Scalability for High Volumes: While digital press speeds are increasing dramatically, they still lag behind high-speed gravure or flexo for very large, continuous runs. Hybrid solutions (digital for variable elements, analog for base colors) or strategically deploying digital for specific SKUs while using analog for high-volume core lines are current strategies. The break-even point for pure digital is constantly shifting upwards.

Color Consistency & Process Control: Maintaining absolute color consistency across different digital presses, substrates, and over time requires sophisticated color management workflows and closed-loop calibration systems. Achieving exact brand color matches, especially on complex film structures, demands expertise.

Total Cost of Ownership (TCO) Analysis: While plate costs vanish and waste reduces, digital inks can be more expensive per unit volume than analog inks. A comprehensive TCO analysis, factoring in tooling savings, reduced waste, inventory reduction, and agility benefits, is essential to justify the investment, especially for mainstream high-volume applications.

Workflow Integration & Expertise: Integrating digital printing seamlessly into existing converting lines (laminating, bag making) requires workflow adjustments and skilled operators who understand both digital technology and the complexities of composite materials.

The future is bright and collaborative. Expect continuous innovation:

-

Faster, Wider Digital Presses: Designed specifically for flexible films, handling wider webs at speeds rivaling analog for more applications.

-

Advanced Inks: Improved adhesion, broader compatibility, enhanced food safety, and sustainable (bio-based, water-based) formulations.

-

Integration of Functionality: Combining printed electronics (NFC, RFID, sensors) directly onto Composite Packaging Bags during digital printing for smart packaging applications.

-

AI-Driven Workflows: Optimizing color management, predictive maintenance, and job scheduling for maximum efficiency in producing digitally printed composite packaging.

-

Circular Economy Focus: Development of digitally printable composite structures designed for easier recyclability (mono-material approaches where possible, compatible inks) or compostability.

The evolution of the Composite Packaging Bag, supercharged by Digital Printing Packaging, signifies more than just a technological shift; it represents a fundamental change in how brands conceive, produce, and utilize flexible packaging. It moves the Composite Packaging Bag from being a cost-effective protective solution to becoming a dynamic, responsive, and highly expressive brand asset central to market success. By embracing this synergy and navigating its challenges, the soft packaging industry is poised to deliver unprecedented value, efficiency, and consumer engagement in the years ahead.

You can visit our website to know more about our flexible packaging pouch: