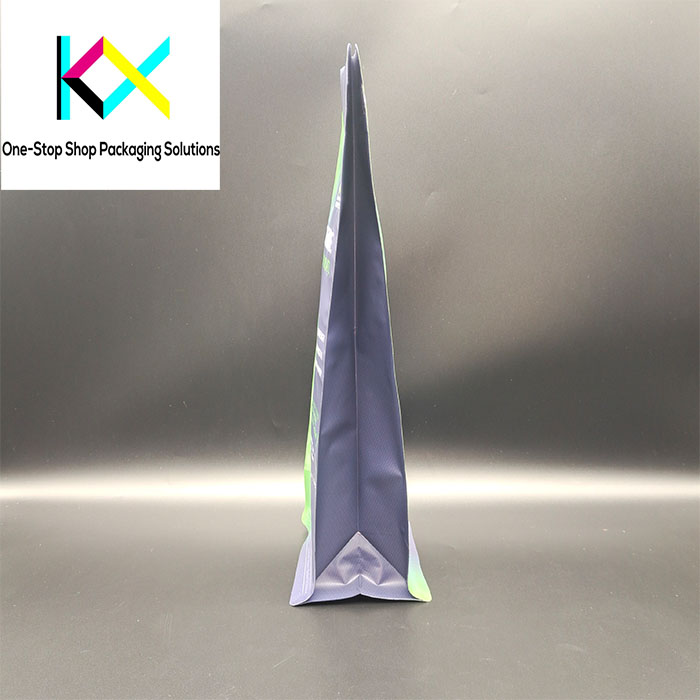

Flat Bottom Zipper Bag: Where Shelf Presence Meets Sustainable Innovation

In the competitive landscape of flexible packaging, the flat bottom zipper bag has emerged as a retail powerhouse – combining freestanding stability with eco-conscious engineering. These self-supporting pouches are redefining product presentation across premium markets while driving unexpected synergies with industrial-grade three side seal pouches. As e-commerce surges and circular economy mandates tighten, both formats are converging to solve the dual challenge of brand impact and planetary responsibility.

The Retail Revolution

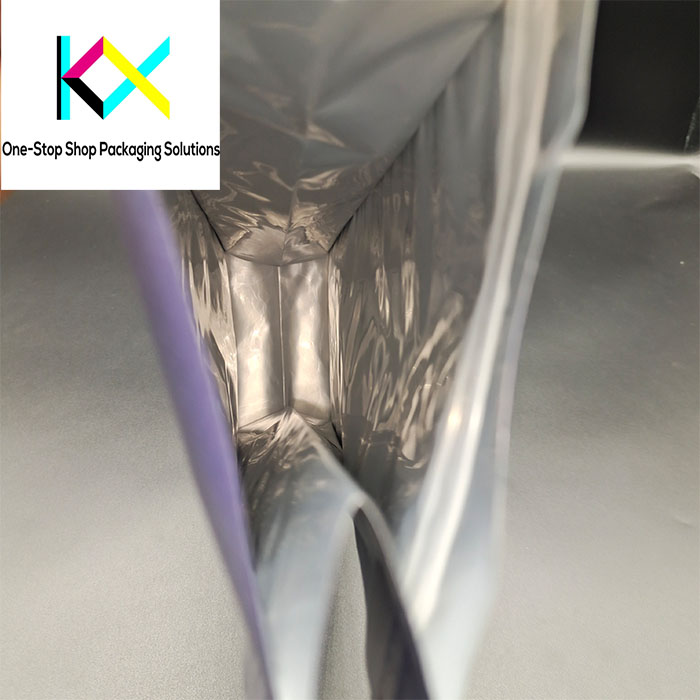

The flat bottom zipper bag dominates shelves through:

360° Brand Canvas: Vertical orientation maximizes graphics space (Lush Cosmetics reports 40% sales lift)

One-Handed Operation: Magnetic zippers require 60% less force vs. traditional seals (ZipTech™ patents)

Logistics Optimization: Nestable empty bags allow 3X more units per pallet

Cross-Industry Adoption:

Specialty Coffee: Blue Bottle’s argon-flushed bags preserve roast freshness for 18 months

Clean Beauty: Youth to the People’s PCR plastic packaging pouch uses ocean-bound plastics

Premium Pet Food: Open Farm’s tear-resistant designs survive claw punctures

Industrial Efficiency Meets Ecology

While flat bottoms rule retail, three side seal pouches drive manufacturing efficiency:

| Advantage | Environmental Impact | Pioneering Application |

|---|---|---|

| 70% faster VFFS line speeds | 35% energy reduction per unit | Castrol’s synthetic oil packs |

| Zero-material-waste nesting | 98% film utilization | Kikkoman soy sauce refills |

| Ultra-thin nano-barriers | 50% plastic reduction | Lavazza’s compostable coffee pods |

Material Breakthrough: BASF’s graphene-reinforced PE films enable three side seal pouches to achieve bottle-level protection at 100μm thickness.

The Sustainability Convergence

Both formats leverage shared innovations:

Detachable Zippers: Schur Star’s Click & Close™ system separates components for recycling

HolyGrail 2.0 Digital Watermarks: Enables automated sorting of PCR-rich flat bottom zipper bag materials

Marine-Degradable PLA: Notpla’s seaweed composites decompose in 26 weeks – adopted for coastal retailers

Regulatory Catalyst: EU’s PPWR requiring 70% recyclability by 2025 forces brands like Unilever to redesign 200+ SKUs using these technologies.

Smart Packaging Evolution

Intelligence transforms both formats:

Dynamic QR Codes: Mori’s smart flat bottom zipper bag tracks avocado ripeness via gas sensors

Self-Healing Films: Dow’s ArcticShield seals repair -30°C micro-fractures in transit

Phase-Change Materials: Tempra’s cooling panels in RXBAR three side seal pouches maintain protein integrity

Industrial applications push boundaries:

→ Anti-static films for electronics (DuPont’s Intelex™)

→ Time-temperature holograms for pharma (Mondi SecureGuard)

→ RFID-enabled reuse tracking for chemical drums

E-Commerce Optimization

The flat bottom zipper bag shines in direct-to-consumer:

Drop-Test Certified: 1.5m impact resistance (ISTA 3A standard)

Compact Refills: 80% smaller than rigid containers

Tamper-Evident Seals: Patented tear-notches for supplements

Meanwhile, three side seal pouches dominate B2B:

Automated palletizing compatibility

Static-dissipative liners for electronics

UV-reactive freshness indicators

Future Frontiers (2025+)

-

Edible Barriers: Rice starch films dissolving during cooking (Kikkoman R&D)

-

Blockchain PCR Verification: Real-time recycled content tracking

-

AI-Optimized Thickness: Machine learning customizing layer density per product

Conclusion: Two Formats, One Sustainable Future

The flat bottom zipper bag and three side seal pouches represent complementary revolutions:

-

Retail Impact: Where consumer experience meets recyclability

-

Industrial Efficiency: Where speed marries material reduction

-

Shared Innovation: Detachable components, smart materials, circular logistics

As brands navigate the $1.2T sustainable packaging shift, those mastering this duality will lead. The future isn’t choosing between formats – it’s leveraging their combined power to build brands that stand tall and ship smart.

You can visit our website to know more about our flexible packaging pouch: