Juice Spout Pouches: The Liquid Packaging Revolution Balancing Convenience and Sustainability

In the rapidly evolving beverage industry, juice spout pouches are emerging as a transformative solution, merging user-friendly design with eco-conscious innovation. These pouches, featuring precision-fit spouts and lightweight structures, are redefining how liquids—from cold-pressed juices to plant-based milks—are packaged, stored, and consumed. As brands face mounting pressure to reduce plastic waste and meet stringent regulations, advancements in liquid packaging bags are proving that functionality and environmental stewardship can coexist.

The Convenience Factor: Spouts That Simplify Life

The juice spout pouch excels in usability. Its integrated spout enables controlled, mess-free pouring—a game-changer for busy households and on-the-go consumers. Brands like Innocent Drinks and Suja Juice use these pouches for their organic smoothie lines, citing a 30% reduction in spillage complaints compared to traditional bottles. For children’s beverages, liquid packaging bags with spill-proof spouts (like Capri-Sun’s redesign) are becoming lunchbox staples, combining safety with portability.

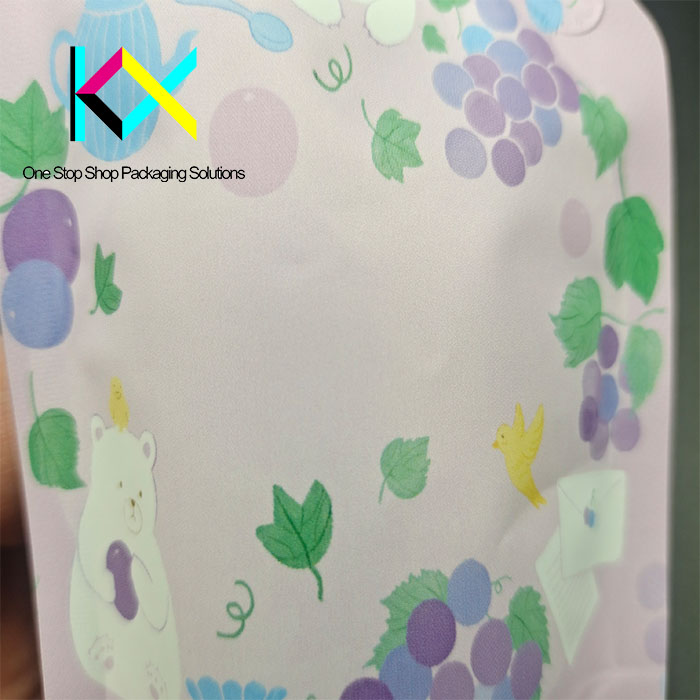

The stand-up design also optimizes shelf space, allowing retailers to display more products vertically—a key advantage in crowded grocery aisles. Startups like Koia leverage this by using eye-catching, digitally printed juice spout pouches to differentiate their protein shakes in competitive markets.

Material Innovation: Closing the Recycling Gap

Historically, juice spout pouches faced criticism for mixed-material construction (plastic spouts + laminated films). Today, breakthroughs in mono-material polyethylene (PE) and polypropylene (PP) structures are making liquid packaging bags fully recyclable. Amcor’s AmLite™ Ultra Recyclable pouch, for instance, uses a single PE layer with barrier coatings, ensuring compatibility with existing recycling streams. Brands like RISE Brewing Co. now use these for their nitro cold brew, diverting 8 tons of plastic annually.

For compostable options, companies like TIPA offer juice spout pouches made from bio-based PBAT and PLA, which decompose in industrial facilities within 90 days. These innovations are critical for juice brands targeting eco-conscious Gen Z buyers—58% of whom prioritize compostable packaging.

Tackling the Infrastructure Challenge

Despite recyclable designs, only 18% of liquid packaging bags are recycled due to inconsistent municipal systems. Brands are tackling this through partnerships and education: Coca-Cola’s Simply Smoothie line includes QR codes on juice spout pouches directing users to local recycling hubs, while PepsiCo’s Tropicana trials deposit schemes where consumers return pouches for discounts.

Legislation is accelerating change. The EU’s Packaging and Packaging Waste Regulation (PPWR) mandates 70% recyclability by 2030, pushing brands like Naked Juice to adopt mono-material juice spout pouches. In the U.S., states like California enforce SB 54, imposing fines for non-recyclable packaging—a catalyst for rapid innovation.

Smart Tech: Intelligence in Every Sip

The next generation of liquid packaging bags integrates smart technology. Embedded RFID tags, tested by Bolthouse Farms, track freshness in real time, sending alerts via smartphone when a carrot juice pouch nears expiration. Temperature-sensitive inks, borrowed from pharmaceutical packaging, now indicate if a juice spout pouch has been exposed to heat, ensuring product safety for brands like Evolution Fresh.

Active packaging is another frontier. Japanese brand Kagome embeds oxygen absorbers in its tomato juice pouches, extending shelf life without preservatives—a concept spreading to cold-pressed juice startups.

The Future: Circularity and Beyond

Emerging trends aim to turn juice spout pouches into circular assets. Australian startup Great Wrap produces pouches from potato waste, which decompose into fertilizer. Meanwhile, blockchain-enabled liquid packaging bags, like those from French brand Bel Group, allow consumers to trace a product’s carbon footprint—appealing to the 65% of shoppers who prioritize ethical brands.

Edible films are also on the horizon. Startups like Notpla are testing seaweed-based coatings for juice spout pouches, which dissolve in water and add a nutrient boost to beverages—an innovation inspired by zero-waste culinary traditions.

Conclusion: A Fluid Path Forward

The juice spout pouch is no longer just a vessel—it’s a symbol of the beverage industry’s commitment to innovation and responsibility. From recyclable mono-materials to smart labels that empower consumers, these pouches exemplify how packaging can evolve without compromising performance.

As regulations tighten and consumer expectations rise, brands must prioritize solutions that pour convenience into sustainability. After all, in the quest for a greener future, every liquid packaging bag—and every sip—counts.

You can visit our website to know more about our flexible packaging pouch: